Tech

What Is Functional Rapid Prototyping? Why Is It So Advantageous To Verify Product Viability Through Functional Rapid Prototyping?

Are you aware of the concept of rapid prototyping? Not sure what it is all about? Well, you have landed at the right place. Rapid prototyping refers to quickly creating a functional model or prototype of a product, system, or idea.

It is a technique used in various industries, including manufacturing, engineering, design, and software development. The primary goal of rapid prototyping service is to validate and test concepts, evaluate design iterations, and gather feedback early in the development cycle.

The process of rapid prototyping typically involves several stages. First, the initial idea or concept is translated into a basic design.

This design is then transformed into a physical prototype using specialized tools, techniques, and technologies. The prototype can be a scaled-down version of the final product or a representation of a specific feature or functionality.

Rapid prototyping again has three subcategories:

The effect to be achieved by rapid prototyping can be divided into visual rapid prototyping, structural rapid prototyping, and functional rapid prototyping.

Visual Prototyping: This category focuses on creating prototypes that primarily represent the appearance or visual aspects of the product. It closely resembles the final product regarding aesthetics, texture, and color.

Structural Prototyping: Structural prototyping emphasizes validating the product’s form, dimensions, and physical structure. The prototypes in this category aim to accurately represent the internal and external structure, including features like internal cavities, overall dimensions, and structural integrity.

Functional Prototyping: Functional prototyping is centered around demonstrating and validating the core functionality and performance of the product. Prototypes in this category are designed to showcase and test the product’s intended tasks or operations effectively.

Here’s what you need to know about functional rapid prototyping:

Functional rapid prototyping is a development approach that involves creating functional prototypes of a product or system to verify its viability, functionality, and performance quickly.

Unlike traditional prototyping methods that focus primarily on visual representation or conceptual models, rapid functional prototyping emphasizes the creation of physical prototypes that can perform the intended functions of the final product.

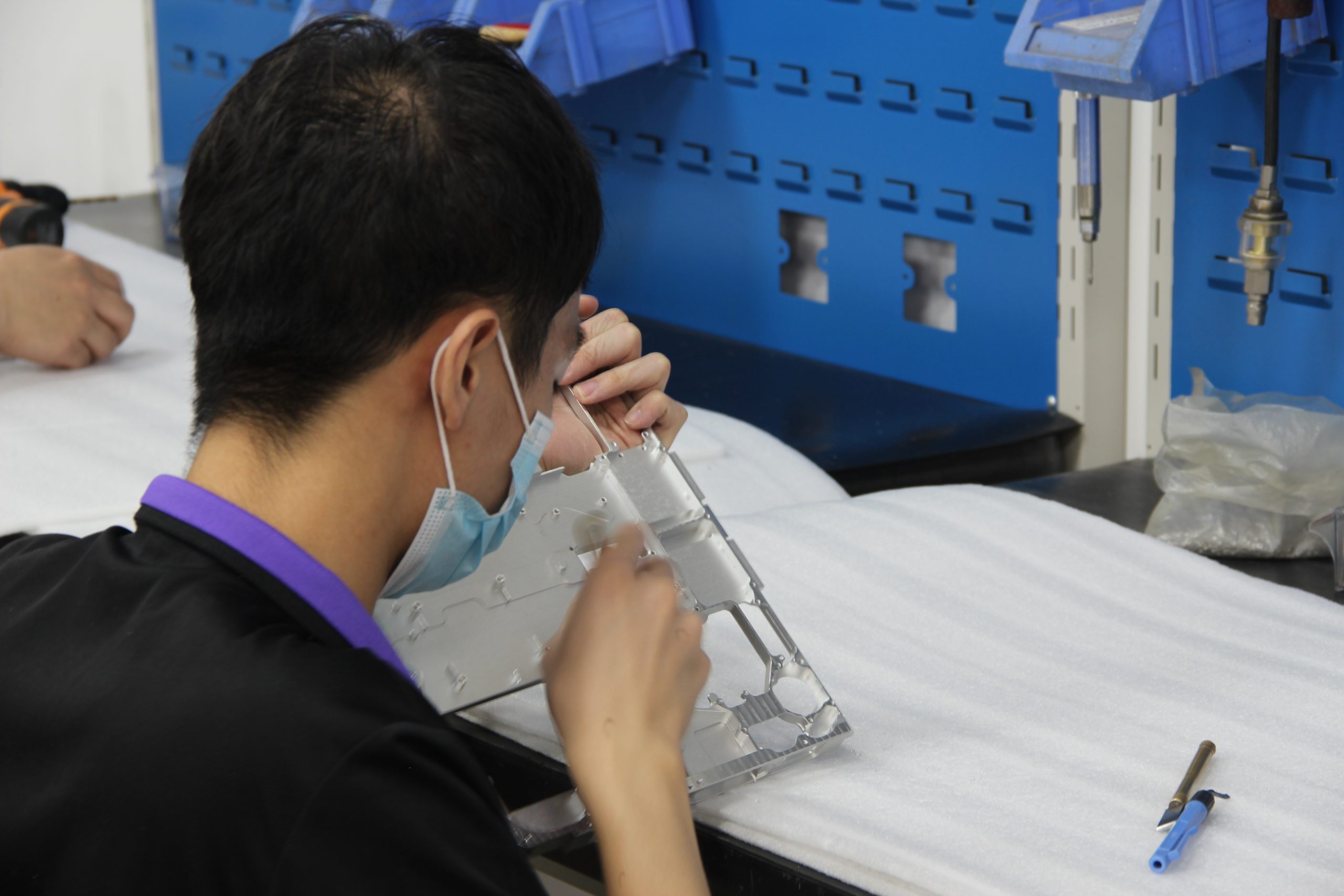

Functional rapid prototyping typically involves using technologies such as 3D printing, CNC machining, or other additive manufacturing techniques to build prototypes. These prototypes are often built using materials that closely resemble the final product, allowing for a more realistic assessment of its functionality and performance.

What are the various advantages of rapid functional prototyping over other prototyping methods?

Functional rapid prototyping offers several significant advantages over other prototyping methods when it comes to verifying product viability:

Early identification of design flaws: By creating functional prototypes, designers and engineers can quickly identify design flaws or technical challenges before investing significant time and resources into full-scale production. This early detection allows for timely modifications and refinements, leading to a more robust and optimized final product.

Improved communication and collaboration: Functional prototypes provide a tangible representation of the product, enabling effective communication and cooperation among various stakeholders, including designers, engineers, clients, and end-users. It helps facilitate a shared understanding of the product’s features, functionality, and potential improvements, leading to better decision-making and alignment among team members.

Real-world simulation and testing: Functional rapid prototypes allow for realistic simulations and product testing in real-world scenarios. By replicating the intended functions of the final product, these prototypes provide valuable insights into its performance, usability, and durability. This enables designers to make informed decisions regarding design changes, materials, and manufacturing processes.

Faster iteration cycles: Traditional prototyping methods can be time-consuming and may require multiple iterations to achieve the desired result. Functional rapid prototyping significantly reduces the time needed for each iteration cycle. As a result, designers can quickly incorporate feedback, make necessary modifications, and retest the prototype, accelerating the overall product development process.

Cost-effective development: Functional rapid prototyping minimizes the risks of developing a new product. Identifying and addressing design flaws early helps prevent costly mistakes during full-scale production. Additionally, functional prototypes can be built using less expensive materials and manufacturing techniques than the final product, reducing development costs.

Enhanced user-centered design: Creating functional prototypes allows designers to involve end-users in the evaluation process at an early stage. By obtaining user feedback and incorporating it into subsequent iterations, designers can create products that better meet user needs, preferences, and expectations. This iterative feedback loop helps achieve a user-centered design approach, resulting in higher user satisfaction and market acceptance.

Validation of technical feasibility: Functional rapid prototyping enables designers to validate the technical feasibility of a product concept. It helps determine if the desired functionality can be achieved using available technologies, materials, and manufacturing processes. This validation ensures that the product can be produced within technical constraints and performance requirements, avoiding potential issues in the later stages of development.

Investor and stakeholder confidence: Functional prototypes demonstrate the product’s potential, increasing investor and stakeholder confidence. The ability to showcase a functional prototype can help secure funding, gain support from key stakeholders, and generate interest from potential customers or partners. This confidence boost can significantly contribute to the success of the product development process.

Market Validation: The ability to produce functional prototypes quickly allows businesses to test their products in the market and gather valuable feedback from potential customers. By obtaining early user insights, companies can validate their product ideas, identify potential market acceptance, and make informed decisions about product improvements and market viability. This helps reduce the risk of developing products that may not meet customer needs or fail to gain market traction.

What are the various applications of functional rapid prototyping?

Functional rapid prototyping finds applications in various industries and can bring several advantages to the product development process. In this response, we will explore some critical applications of functional rapid prototyping.

Product Design and Development: Functional rapid prototyping is crucial in product design and development. It lets designers and engineers quickly iterate and refine their concepts, turning ideas into tangible prototypes. By creating functional prototypes early in the design process, designers can validate their ideas, test different functionalities, and gather stakeholder feedback, leading to more informed design decisions.

Manufacturing and Assembly: Functional rapid prototyping is widely used in manufacturing and assembly processes. It allows engineers to test the feasibility of manufacturing techniques, evaluate assembly procedures, and optimize the production line. By creating functional prototypes, manufacturers can identify and resolve potential issues, such as fitment problems, assembly challenges, or manufacturing constraints, before full-scale production, thereby reducing costs and time-to-market.

User Testing and Validation: Functional rapid prototyping is invaluable in user testing and validation. It allows designers to create prototypes that closely resemble the final product regarding functionality and aesthetics. End-users can test these prototypes to evaluate usability, ergonomics, and overall user experience. User feedback collected during this phase can guide further design iterations and improvements, ensuring that the final product meets user expectations and needs.

Functional Testing and Performance Evaluation: Functional rapid prototyping enables engineers to assess a product’s or part’s performance before committing to full-scale production. By creating functional prototypes, they can conduct various tests to evaluate structural integrity, material behavior, thermal properties, and mechanical functionality. This helps identify design flaws, optimize performance, and ensure the final product meets the required specifications and standards.

Concept Communication and Marketing: Functional prototypes are excellent tools for communicating design concepts and marketing products. These prototypes provide a tangible representation of the product’s features and functionalities, making it easier for stakeholders and potential customers to understand and engage with the design. Functional prototypes can be showcased at trade shows, presentations, or user demonstrations, creating a buzz and generating interest in the product.

Customization and Personalization: Functional rapid prototyping is particularly beneficial when it comes to the customization and personalization of products. Manufacturers can create unique, one-of-a-kind products tailored to specific customer requirements by using rapid prototyping techniques. This ability to quickly produce customized prototypes allows for rapid feedback and adjustments, ensuring that the final product meets the customer’s expectations.

Some thoughts to end with:

In this way, rapid functional prototyping offers numerous advantages when verifying product viability. By creating functional prototypes, designers and engineers can identify design flaws early, facilitate effective communication and collaboration, conduct realistic testing, iterate rapidly, reduce development costs, achieve user-centered design, validate technical feasibility, and enhance investor and stakeholder confidence.

These benefits make rapid functional prototyping a valuable approach in the product development lifecycle, helping to increase the profitability of the products. There are a lot of applications of rapid functional prototyping as well, which again makes this method stand out from the crowd.

To know more about functional rapid prototyping, you may contact our rapid prototyping company, and we will give you the details regarding the same.

SEE ALSO: 4 Reasons Why AI Will Never Supersede Humans: The Future Of Artificial Intelligence (AI)