Automotive

Fortune Cross Automotive Precision Shaft Factory in Thailand Demands Quality Control

In the highly competitive automotive industry, precision and quality are paramount. Automotive precision shafts, which are integral components in vehicles, must be manufactured with utmost accuracy. Fortune Cross Thailand, a reputed precision shaft manufacturer, exemplifies the importance of inspection and testing in quality control. This article explores the critical role these processes play in ensuring top-notch automotive precision shaft factory in Thailand.

Automotive precision shafts are mechanical components meticulously engineered to transmit torque and rotation. They are indispensable for the seamless functioning of various systems in vehicles, such as transmission, steering, and engine components. Precision shaft factory in Thailand plays a significant role in producing these vital components.

With quality control being the linchpin for ensuring safety, performance, and durability in the automotive sector, even a slight deviation in quality can have far-reaching consequences. Thus, precision shaft manufacturers in Thailand are committed to maintaining high standards in production and quality control.

Overview of Automotive Precision Shafts

Precision shafts are pivotal elements in the automotive industry, and their production involves intricate precision shaft machining processes. At Fortune Cross Thailand, the range of shafts produced is extensive and made from high-grade materials to ensure optimum performance. In this section, we delve into the role of precision shafts in the automotive industry, the various types produced by Fortune Cross Thailand, and the materials employed in manufacturing these shafts.

Role of Precision Shafts in the Automotive Industry:

- Power Transmission

Precision shafts are essential for transmitting power from the engine to other components, ensuring the vehicle operates efficiently.

- Structural Support

They provide crucial support within mechanical systems, helping to maintain structural integrity during operation.

- Reducing Friction and Wear

The high precision in their machining ensures minimal friction between moving parts, which reduces wear and tear and prolongs the lifespan of components.

Types of Precision Shafts available in Thailand:

- Shaft Lifter Arm (12×128.9 mm)

This is used in the valve train of engines to help control valve movement, ensuring proper timing and performance.

- Carburetor Shaft (6.0×67.6 mm)

A vital part of the carburetor in motorcycles, this shaft plays a crucial role in mixing air and fuel in the right proportion for combustion.

- Shaft Gear Shift (12.0×280.5 mm)

Integral to the transmission system, this shaft is responsible for helping the vehicle switch between gears smoothly and efficiently.

Materials Used for Manufacturing Precision Shafts:

- Japanese Steel (S45C)

A high-quality carbon steel, S45C is used for its strength and durability, making it suitable for components that undergo a lot of stress.

- SUS420J2 Stainless Steel

Known for its resistance to corrosion and high hardness, this steel is often used in applications where both durability and a high-quality finish are necessary.

- Additional Materials

Fortune Cross also utilizes other high-grade materials such as SUS420F, SUS303, and more, tailoring material choices to specific application requirements.

With precision shaft machining at the forefront, Fortune Cross Thailand’s dedication to producing high-quality precision shafts is evident in the materials they choose and the diverse range of products they manufacture. These shafts play a vital role in the automotive industry, and their quality and precision are paramount.

Importance of Inspection in Quality Control

Precision shafting is a process that requires meticulous attention to detail. Inspection plays a pivotal role in quality control for precision shafting, ensuring that the shafts meet the required specifications and performance criteria. Here, we will delve into the three main aspects of inspection that are fundamental in quality control: ensuring dimensional accuracy, material quality inspection, and surface finish inspection.

Ensuring Dimensional Accuracy:

- Diameter Control:

- Critical Role: An accurate diameter is crucial for the proper fitting of the shaft in the assembly.

- Operational Reliability: Ensures that the precision shaft can operate without excessive vibration or misalignment.

- Length Size Control:

- Compatibility: Controlling the length is vital for ensuring that the shaft fits seamlessly with other components.

- Structural Integrity: Accurate length helps in maintaining structural integrity and preventing over-stressing of components.

Material Quality Inspection:

- Ensuring the Use of High-Quality Materials:

- Durability: High-quality materials prolong the lifespan of the precision shaft, making it more resistant to wear and tear.

- Performance: Better materials contribute to the optimal performance of the shaft, as they can handle greater stresses and loads.

- Detecting Material Defects:

- Preventive Measure: Identifying material flaws early helps in preventing catastrophic failure in application.

- Cost-Effective: It is more economical to detect and address material defects at the manufacturing stage than dealing with breakdowns later on.

Surface Finish Inspection:

- Importance of Surface Finish:

- Friction Reduction: A smooth surface finish is vital in reducing friction, which in turn lowers the wear rate.

- Heat Dissipation: Improved surface finish enhances heat dissipation, which is crucial for the performance of the shaft.

- How It Affects Performance:

- Efficiency: A proper surface finish ensures that there is minimal energy loss due to friction, leading to higher operational efficiency.

- Maintenance: Well-finished surfaces require less maintenance and are less likely to cause premature failure of surrounding components.

Testing Procedures in Quality Control

Quality control is a linchpin in the manufacturing of automotive precision shafts. To ensure that these shafts meet the highest standards of durability, strength, and performance, a variety of testing procedures are employed. Here, we take a closer look at the different types of testing that are integral to maintaining the excellence of precision shafts manufactured by Fortune Cross Thailand.

Mechanical Testing:

Mechanical testing is instrumental in evaluating how materials behave under different conditions, ensuring that the shafts can endure the physical demands during use.

- Stress Tests

Stress tests are conducted to gauge how materials respond to different levels of stress. By applying force to the material and measuring its deformation and strength, stress tests are critical in understanding if the material is suitable for withstanding the operational demands.

- Fatigue Tests

Fatigue tests are essential for assessing the endurance of materials under cyclic or repeated loads. By subjecting the material to repeated loading and unloading, these tests simulate real-world conditions and are crucial for predicting lifespan and preventing premature failure.

Non-Destructive Testing (NDT):

NDT is vital for evaluating the integrity of materials and finished products without causing any damage, making it perfect for detecting internal defects that might not be externally visible.

- X-ray Testing

X-ray testing is utilized for detecting internal flaws and irregularities in materials. By using X-rays to inspect the internal structure and observing variations in absorption levels, internal flaws become discernible in the X-ray images.

- Ultrasonic Testing

Ultrasonic testing is an invaluable technique for inspecting the internal structure and integrity of materials. It uses high-frequency sound waves that traverse through the material, and the analysis of echo patterns is employed to identify any discontinuities or defects inside.

Performance Testing:

Performance testing ensures that the shafts are fully equipped to function effectively under conditions akin to real-world applications.

- Load Testing

Load testing verifies the shaft’s ability to endure specific loads during operation. This testing process involves applying forces that simulate the loads experienced in service to validate that the shaft will function as intended under these conditions.

- Operational Testing

Operational testing is employed to ensure that the shaft performs optimally in realistic environments. By simulating real-world operating conditions, this testing procedure evaluates the performance, efficiency, and reliability of the shaft.

Compliance with International Standards:

Ensuring compliance with international standards is crucial for products to meet globally recognized quality benchmarks.

- Adherence to Japanese Standards

Fortune Cross Thailand’s adherence to Japanese standards signifies a commitment to high-quality manufacturing processes. Japanese standards are globally renowned for their rigor in quality control, and adherence to them ensures the production of superior precision shafts.

- Certifications and Accreditations

Having certifications and accreditations ensures international recognition for the quality of products. It signifies that the products have undergone an independent assessment and satisfy international quality standards.

A Leading Precision Shaft Factory in Thailand

In the landscape of precision shaft manufacturing, there is a particular factory in Thailand that has set the bar high. This case study aims to shed light on the effective quality control processes, real-world applications, and customer feedback associated with this factory without explicitly mentioning its name.

Quality Control Processes Employed by Reliable Factories:

- Stringent Material Inspection

The factory ensures the materials used are of the highest quality, often utilizing high-grade steel such as S45C and SUS420J2, which are critical for the durability and performance of the precision shafts.

- Dimensional Accuracy Checks

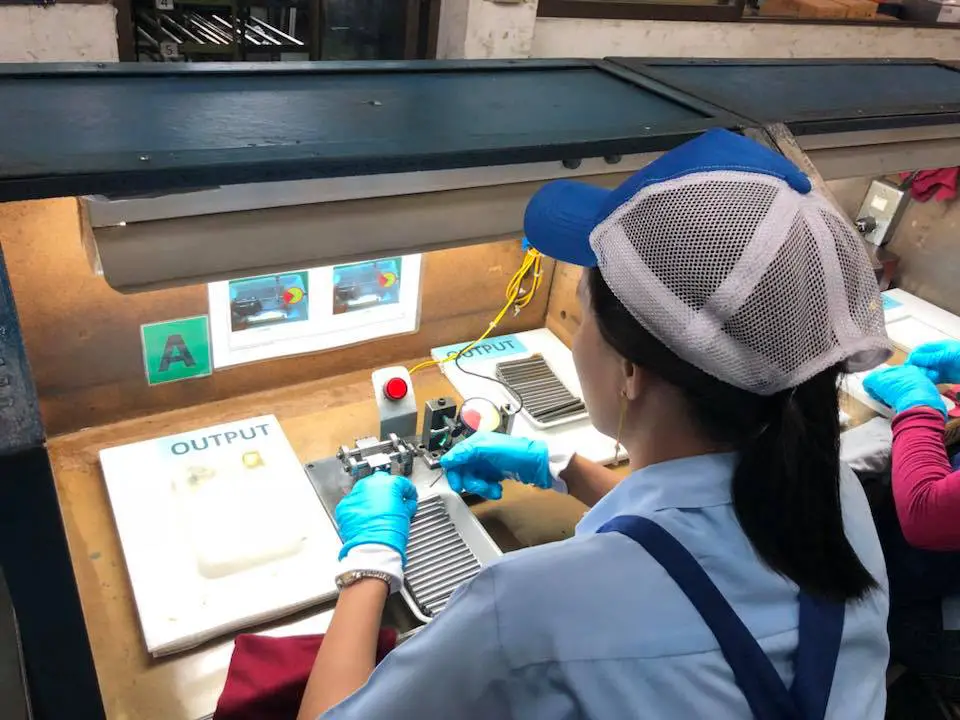

Advanced measuring instruments are deployed to confirm the shaft dimensions are within prescribed tolerances, ensuring compatibility and efficient operation.

- Surface Finish Evaluation

The factory employs surface roughness testers to ensure that the surface finish of its products meets the required standards, thereby reducing friction and increasing the lifespan of the shafts.

- Regular Equipment Calibration

By calibrating its manufacturing equipment routinely, the factory guarantees consistent production quality.

- Adherence to International Standards

The factory complies with Japanese standards and other international benchmarks to ensure the quality and performance of its products.

Real-World Examples of Inspection and Testing for Precision Shafts:

- Customized Production for Clients

This factory has been noted for manufacturing customized precision shafts that meet specific client requirements. This involves special inspection and testing procedures to ensure client satisfaction.

- Swift Rectification of Defects

In instances where minor deviations or defects have been detected, the factory is known for acting promptly and effectively to maintain product integrity.

- Consistent High-Quality Output

Through the successful implementation of quality control processes, the factory has consistently delivered high-quality precision shafts to the market.

Customer Feedback and Reputation for Quality:

- High Customer Satisfaction

The factory has received positive feedback from customers regarding the quality and durability of their precision shafts.

- Recommendations and Referrals

A considerable number of new customers are derived through referrals, which suggests a high level of satisfaction among existing clients.

- Strong Market Presence

A steadfast commitment to quality has enabled this factory to establish a substantial market presence and become one of the preferred manufacturers of precision shafts.

In conclusion, this leading precision shaft factory in Thailand exemplifies the importance of rigorous quality control processes. Its strong market presence and positive customer feedback attest to the high standards maintained in the manufacturing of precision shafts.

The Future of Quality Control in Precision Shaft Manufacturing

As the automotive industry evolves, precision shaft manufacturers are confronted with new challenges and opportunities. Advancements in technology, shifts in industry trends, and the growing importance of sustainability are shaping the future of quality control in precision shaft manufacturing. This section delves into these key aspects, providing insights into what lies ahead for manufacturers in this domain.

- Technological Advancements in Inspection and Testing

- Artificial Intelligence (AI) and Machine Learning

AI algorithms and machine learning models are being integrated into inspection systems to predict and detect defects with greater accuracy. These technologies help in reducing human error and improving overall quality.

- 3D Scanning and Imaging

Modern 3D scanning and imaging techniques allow for highly detailed inspection of shaft dimensions and surface topology. This facilitates quicker and more accurate detection of deviations from specified tolerances.

- Robotic Process Automation (RPA)

Automating repetitive inspection tasks with robots not only increases efficiency but also ensures consistency in quality. RPA is particularly useful in high-volume production environments.

- Internet of Things (IoT)

IoT devices and sensors can monitor the manufacturing process in real time, enabling immediate feedback and adjustment. This leads to improved quality control and reduced waste.

- Industry Trends

- Customization and Personalization

As consumer demands diversify, there is a growing trend toward customization and personalization. Precision shaft manufacturers are adapting by offering more varied and tailored products without compromising quality.

- Integration of Big Data Analytics

Harnessing big data analytics allows manufacturers to gain insights from large datasets. This can be crucial for identifying patterns, trends, and potential areas of improvement in quality control processes.

- Globalization and Supply Chain Optimization

Precision shaft manufacturers are expanding their reach and optimizing supply chains to meet global demands. This requires stringent quality control to adhere to varying international standards.

- Sustainability and Environmental Considerations

- Use of Recycled Materials

The integration of recycled materials into manufacturing processes reflects a growing commitment to sustainability. This helps in reducing environmental impact and often comes with cost benefits.

- Energy-Efficient Manufacturing Processes

Implementing energy-efficient technologies and practices reduces the carbon footprint of manufacturing. This is not only environmentally responsible but can also be a selling point, especially for eco-conscious consumers.

- Sustainable Waste Management

Adopting sustainable waste management practices, such as recycling and repurposing waste material, minimizes environmental pollution and contributes to a circular economy.

Final Thoughts: Embracing Excellence in Automotive Precision Shafts Through Quality Control

Quality control, through meticulous inspection and testing, is indispensable in the production of automotive precision shafts. Fortune Cross Thailand exemplifies the implementation of these principles, producing exceptional products that cater to the automotive industry. Stakeholders must embrace rigorous quality control methods to ensure safety, performance, and durability.

Engage with the future of automotive precision manufacturing by investing in quality. Choose Fortune Cross Thailand for excellence in precision shafts.