Tech

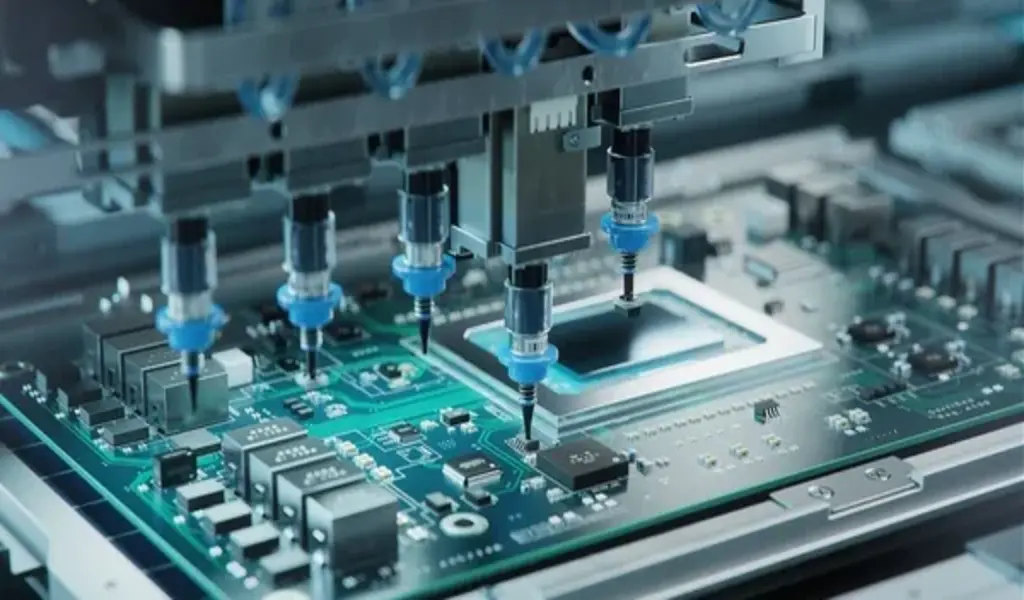

Exploring PCB Assembly: Tailoring Circuit Board Manufacturing to Unique Industry Needs

Printed Circuit Boards (PCBs) are very important in modern electronics. They are like the foundation of electronic devices. These simple but important parts are in high demand because industries need customized PCBs that meet their specific and sometimes difficult requirements.

In this article, we will dive into the world of PCB assembly. We will learn about the complex processes that manufacturers use to create circuit boards that are specifically designed for different industries.

Customization for Aerospace and Defense

The aerospace and defense industries are well-known for having very strict rules. This means that printed circuit boards (PCBs) used in these industries must meet and go above and beyond what is expected. Customization in this area involves selecting specific materials and creating intricate designs.

These changes ensure that PCBs are not just very good but extremely strong and efficient, able to handle even the toughest situations. Whether it’s the challenges of being in high places, constant shaking, or changing temperatures, these PCBs must be designed to last and perform well.

Medical Device PCBs

The world of medical device circuit boards works with very precise and strict standards. To meet these strict requirements, customization involves carefully choosing safe materials for the body. We pay special attention to making things smaller and stronger. These small circuit boards are made to work well with medical devices that are small and easy to carry. They need to work perfectly and be safe for patients to use. In the complex field of medical technology, there is no space for settling.

Automotive Electronics

The ever-changing world of car electronics is always evolving. As a result, the PCBs made for vehicles are becoming increasingly complex. Customization is very important because these PCB assembly need to be stronger to handle the tough conditions inside cars. This means being able to handle very hot or very cold temperatures, strong shaking, and having space for advanced safety and entertainment features. Making sure that the electronic system in modern cars works well and doesn’t have any problems is important.

IoT and Wearable Devices

The Internet of Things (IoT) and wearable devices need small and power-efficient PCBs. In this area, customization focuses on saving energy, making things smaller, and making wireless communication work smoothly. As the Internet of Things (IoT) grows and wearable technology becomes more common, customized PCBs (printed circuit boards) are becoming very important in these new devices. They help these devices work well and use energy efficiently.

Communication Infrastructure

The phone and internet industry uses special circuit boards to send information quickly. In this field, customization means using special materials and carefully optimizing signal integrity. These changes ensure that communication networks stay working without any breaks so that data can be sent quickly and smoothly. This is very important in our world, where everything is connected.

Consumer Electronics

In gadgets, circuit boards must be small, use less energy, and have cool features. The changes made here are all about making PCBs that are not only stylish and compact but also use less power. Nowadays, it’s common for devices to have wireless charging and advanced displays. Customized PCBs play a big role in making these features possible and improving the user’s experience.

PCBs for Space Exploration

Space missions take place in an extremely challenging environment. PCBs going to space must work perfectly even in tough situations like radiation, hot and cold temperatures, and space. Customization, in this case, means using special components and materials that can withstand radiation. This is done to make sure that the electronics on the spacecraft stay dependable during the entire mission.

Green Electronics

The electronics industry is now focusing on being more environmentally friendly and sustainable. Customization in this system means choosing materials that are very effective and good for the environment. These materials can be recycled. Energy-efficient designs help save money by reducing operating costs. They also help guard the environment by reducing carbon emissions produced. This is in line with efforts to make electronic devices more environmentally friendly.

Conclusion

In a world where technology keeps advancing, PCB assembly is a constantly changing and growing field. Manufacturers are always at the forefront of coming up with new ideas and changing how they do things to meet the different needs of different industries. Making things exactly how you want them is important in designing and making PCBs.

PCBs, or printed circuit boards, are special components that play a crucial role in the technology we use daily. They are like hidden heroes that help power our devices and make them work efficiently.

SEE ALSO: The Future Of The Internet: What Happens If Google Loses Its Antitrust Battle?