Learning

How 3D Models are Designed for Product Packaging

In today’s competitive market, product packaging plays a crucial role in attracting customers and influencing their purchasing decisions. The rise of e-commerce has further emphasized the importance of visually appealing packaging designs. With advancements in technology, designing 3D models for product packaging has become an invaluable tool for marketers and designers. In this article, we will explore the techniques and best practices involved in creating captivating 3D models for product packaging.

Understanding the Purpose of 3D Packaging Models

Before delving into the technical aspects of designing 3D models for product packaging, it is important to understand the purpose they serve. 3D packaging models offer several benefits to designers, marketers, and stakeholders involved in the packaging design process.

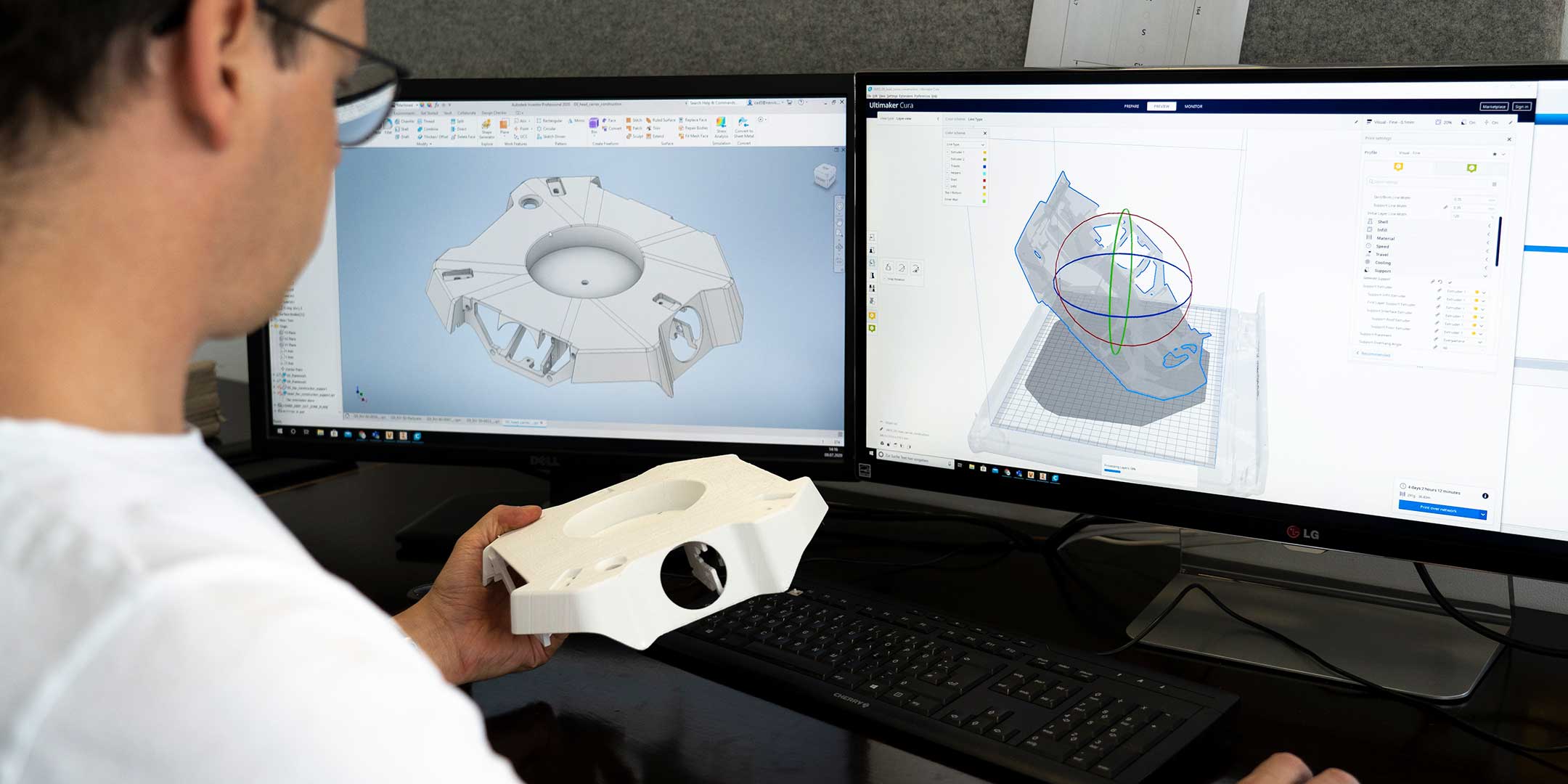

Visual representation: One of the primary purposes of 3D packaging models is to provide a realistic visual representation of the packaging design. Unlike 2D drawings or sketches, 3D models offer a three-dimensional view that enables designers and stakeholders to visualize the final product from different angles. This allows for a better understanding of how the packaging will look and function in the real world.

By creating a detailed and accurate 3D representation of the packaging design, designers can identify any potential design flaws or improvements before investing in physical prototypes. This saves time and resources that would have otherwise been spent on creating multiple physical prototypes.

Testing and validation: 3D packaging models serve as a valuable tool for testing and validating various design elements of 3d modeling. Designers can experiment with different colors, textures, materials, and finishes to see how they impact the overall aesthetic appeal of the packaging. They can also test different sizes, shapes, and configurations to ensure optimal functionality and practicality.

3D models allow designers to simulate how the packaging will interact with the product, such as fitting the product securely, protecting it from damage, and providing easy access to the contents. This helps in identifying any potential issues and making necessary adjustments before moving forward with the production process.

Marketing and promotion: High-quality 3D renders of packaging designs can be utilized for marketing and promotional purposes. These renders can be showcased on websites, social media platforms, advertisements, and product catalogs. By presenting the packaging design in a visually appealing and realistic manner, companies can attract and engage potential customers.

Software Tools for Creating 3D Packaging Models

Creating 3D packaging models requires the use of specialized software tools that offer powerful features for modeling, rendering, and animation. These tools enable designers to bring their packaging designs to life in a virtual environment. Here are some popular software tools used for creating 3D packaging models:

Autodesk 3ds Max: Autodesk 3ds Max is a comprehensive 3D modeling, animation, and rendering software widely used in the design industry. It provides a robust set of tools for creating intricate packaging designs with precise dimensions and realistic materials. With its intuitive interface and extensive plugin support, 3ds Max offers versatility and flexibility for designers to explore various design options.

Blender: Blender is a free and open-source 3D creation suite that has gained significant popularity in recent years. It offers a wide range of features for modeling, animation, sculpting, and rendering, making it suitable for creating realistic packaging visuals. Blender’s powerful rendering engine, Cycles, allows for high-quality renders with realistic lighting and materials. The software also has an active community that contributes to its continuous development and provides extensive learning resources.

Adobe Dimension: Adobe Dimension is part of the Adobe Creative Cloud suite and is specifically designed for creating 3D product mockups, including packaging designs. It offers a user-friendly interface that allows designers to easily import 2D design assets and transform them into 3D representations. With Dimension, designers can quickly visualize and iterate on packaging designs, apply materials and textures, and set up lighting and camera angles for realistic renders.

Rhino 3D: Rhino 3D, also known as Rhinoceros, is a versatile 3D modeling software widely used in industrial design and product development. It offers powerful modeling tools and supports a wide range of file formats, making it compatible with other software used in the design workflow. Rhino 3D provides features for precise modeling of packaging structures and the creation of complex shapes and patterns. It also integrates well with rendering engines like V-Ray or KeyShot for high-quality visualization.

Designing Techniques for 3D Packaging Models

When creating 3D packaging models, there are several techniques and considerations that can enhance the overall appeal and realism of the final output. Here are some important design techniques to keep in mind:

Accurate dimensions: One of the key aspects of designing 3D packaging models is ensuring that the model accurately represents the physical dimensions of the packaging. This includes factors such as length, width, and height. Paying close attention to these measurements helps maintain authenticity and ensures that the final packaging design aligns with the intended specifications.

Textures and materials: Utilizing high-resolution textures and materials is essential for creating realistic packaging visuals. Consider the specific materials used in the actual packaging, such as cardboard, plastic, or glass. Apply appropriate textures and material properties to simulate the look and feel of these materials accurately. Pay attention to details such as reflections, surface imperfections, and textural variations to enhance the visual authenticity of the packaging model.

Lighting and shadows: Implementing realistic lighting techniques is crucial for creating convincing 3D packaging models. Proper lighting helps to bring out the form, texture, and details of the packaging design. Consider the type of lighting environment in which the product will be displayed or used, whether it’s natural daylight, studio lighting, or ambient lighting. Accurately placing light sources and adjusting their intensity and color can create shadows and highlights that add depth and realism to the 3D packaging model.

Typography and branding: Incorporating typography and branding elements onto the packaging model helps stakeholders visualize the final product’s branding and messaging. Ensure that the text on the packaging is legible and aligned with the overall design. Pay attention to factors such as font choice, size, placement, and color to create a harmonious and aesthetically pleasing composition. Consider how the typography and branding elements interact with other design elements of the packaging, such as graphics or product images.

Environmental context: When designing 3D packaging models, it is important to consider the environmental context in which the product will be displayed or used. Incorporate appropriate contextual elements, such as backgrounds or scenes, that complement the packaging design and enhance its visual impact. For example, if the product is a food item, the packaging model could be placed in a kitchen setting or a natural outdoor environment. Adding contextual elements helps provide a sense of scale, context, and visual storytelling.

Iterative Design and Collaboration

Iterative design and collaboration are essential components of the process of creating 3D packaging models. They enable designers to refine their designs, gather feedback, and ensure that the final packaging design meets the desired objectives. Here’s a detailed explanation of iterative design and collaboration in the context of 3D packaging models:

Iterative design: Iterative design involves a cyclical process of designing, prototyping, testing, and refining a product or design. When applied to 3D packaging models, it allows designers to continuously improve and optimize the packaging design based on feedback and real-world considerations.

During the iterative design process, designers create an initial 3D packaging model based on their understanding of the requirements and objectives. This initial model serves as a starting point for further exploration and refinement. Designers then seek feedback from stakeholders, clients, and potential consumers to gather insights and perspectives.

Based on the feedback received, designers make necessary adjustments and modifications to the 3D packaging model. These iterations can involve changes to dimensions, colors, materials, typography, and other design elements. Each iteration brings the packaging design closer to its desired form, addressing any concerns or issues identified during the feedback stage.

The iterative design process helps ensure that the final packaging design is thoroughly tested, refined, and optimized. It allows designers to identify and address potential problems or challenges early on, reducing the risk of costly revisions or rework in later stages of the design process.

Collaboration: Collaboration plays a crucial role in the design and development of 3D packaging models. Effective collaboration involves the involvement and input of various stakeholders throughout the design process.

Designers collaborate with clients, marketing teams, and other relevant stakeholders to align the packaging design with the brand’s vision, marketing goals, and target audience preferences. Collaborative discussions help ensure that the 3D packaging model effectively communicates the desired messaging and brand identity.

Additionally, collaboration enables designers to gather feedback and insights from stakeholders. This feedback can come in the form of suggestions, critiques, or requests for modifications. By incorporating diverse perspectives and expertise, designers can refine and enhance the packaging design, making it more appealing, functional, and aligned with the intended objectives.

Optimization for Different Platforms

When creating 3D packaging models, it’s important to consider the platform or medium through which the models will be presented or utilized. Different platforms have varying technical requirements and constraints that must be taken into account to ensure optimal performance and compatibility. Here are some key considerations for optimizing 3D packaging models for different platforms:

Web and mobile applications: If the 3D packaging models are intended for web or mobile applications, optimization is crucial to ensure smooth loading and rendering on various devices and network conditions. Here are some optimization techniques:

Polygonal optimization: Reduce the complexity of the 3D model by optimizing the polygon count without sacrificing visual quality. Simplify the geometry by removing unnecessary details or using techniques such as level-of-detail (LOD) models.

Texture optimization: Optimize the size and resolution of textures used in the packaging model to reduce file size and loading time. Consider using texture compression formats that offer a good balance between image quality and file size, such as JPEG or PNG.

Streaming and progressive loading: Implement streaming techniques to load 3D models progressively, allowing users to view and interact with the packaging model while it continues to load in the background. This approach minimizes initial loading times and improves the overall user experience.

Virtual reality (VR) and augmented reality (AR): If the 3D packaging models are intended for VR or AR applications, optimization is crucial to maintain high frame rates and ensure a smooth and immersive experience. Consider the following optimization techniques:

Level of detail (LOD): Implement LOD models that dynamically adjust the level of detail based on the user’s position and distance from the packaging model. This helps optimize performance by reducing the complexity of the model when it’s farther away from the user.

Optimization for Different Platforms

When designing 3D packaging models, it is essential to optimize them for different platforms to ensure optimal performance and compatibility. Here are some key considerations for optimizing 3D packaging models for different platforms:

Web and Mobile Applications

For 3D packaging models intended for web or mobile applications, optimization is crucial to ensure smooth loading and rendering on various devices and network conditions. Consider the following techniques:

Polygonal Optimization: Reduce the complexity of the 3D model by optimizing the polygon count. This involves simplifying the geometry, removing unnecessary details, or implementing techniques such as level-of-detail (LOD) models. By reducing the polygon count, you can improve loading times and rendering performance without compromising visual quality.

Texture Optimization: Optimize the size and resolution of textures used in the packaging model. Compress textures to reduce file size and loading time. Consider using texture compression formats like JPEG or PNG to strike a balance between image quality and file size.

Streaming and Progressive Loading: Implement streaming techniques to load 3D models progressively. This approach allows users to view and interact with the packaging model while it continues to load in the background. By implementing progressive loading, you can minimize initial loading times and enhance the user experience.

Virtual Reality (VR) and Augmented Reality (AR)

For 3D packaging models in VR or AR applications, optimization is crucial to maintain high frame rates and provide a smooth and immersive experience. Consider the following optimization techniques:

Level of Detail (LOD): Implement LOD models that dynamically adjust the level of detail based on the user’s position and distance from the packaging model. This technique optimizes performance by reducing the complexity of the model when it is farther away from the user’s viewpoint.

Occlusion Culling: Use occlusion culling techniques to optimize rendering. By only displaying objects that are visible to the user, you can minimize unnecessary rendering calculations and improve overall performance.

Real-time Lighting and Shading: Utilize optimized lighting and shading techniques specifically designed for real-time rendering in VR and AR environments. This may involve pre-baked lighting, light probes, or real-time global illumination solutions to achieve realistic lighting effects without sacrificing performance.

Conclusion

Designing 3D models for product packaging requires careful consideration of various factors, including the purpose of the packaging, software tools, designing techniques, iterative design, collaboration, and optimization for different platforms. By understanding the purpose of the 3D packaging models, designers can effectively communicate the intended message and align the design with the product’s requirements.

Using software tools and 3D modeling services are specifically designed for creating 3D packaging models enhances efficiency and enables designers to unleash their creativity. Employing designing techniques such as accurate dimensions, textures, lighting, and typography ensures a realistic and visually appealing representation of the packaging design. The iterative design process and collaboration with stakeholders facilitate continuous improvement, incorporating feedback and refining the packaging design iteratively.

Optimizing 3D packaging models for different platforms, whether it’s web and mobile applications, VR and AR experiences, or offline rendering and presentations, is crucial for achieving optimal performance, compatibility, and visual quality. By considering platform-specific optimization techniques, designers can ensure a seamless user experience and an impactful presentation of the packaging design.

Designing 3D models for product packaging is an exciting and multidimensional process that requires a blend of creativity, technical skills, and attention to detail. By employing the techniques and best practices discussed in this blog, designers can create stunning and engaging 3D packaging models that effectively showcase products, captivate consumers, and contribute to the success of the overall branding and marketing efforts.