Learning

8 Steps to Custom Online CNC Machining Services

Custom online CNC machining services refer to the manufacturing process of creating custom-designed parts using a computer numerical control (CNC) machine. The process involves using computer-aided design (CAD) software to design the part, which is then translated into machine code and sent to a CNC machine for production.

Online CNC machining services offer customers the ability to design and order custom parts online from anywhere in the world. This allows for fast and convenient manufacturing of custom parts without the need for physical visits to a machine shop.

Some benefits of online CNC machining services include:

Customization:

Customers can design and order custom parts to their exact specifications.

Cost-effective:

Online CNC machining services can be more cost-effective than traditional machining methods because they eliminate the need for physical visits to a machine shop.

Fast turnaround time:

Online CNC machining services can offer faster turnaround times than traditional machining methods because the entire process is automated.

High-quality parts:

CNC machines are capable of producing high-quality parts with a high degree of accuracy and precision.

Material variety:

Online CNC machining services can work with a wide variety of materials, including metals, plastics, and composites.

Online CNC machining services offer a convenient and cost-effective way to produce custom-designed parts with a high degree of accuracy and precision.

CNC Turning and CNC Milling: Understanding the Differences and Applications

CNC turning and CNC milling are two different manufacturing processes used to create complex parts from various materials. While both processes utilize computer numerical control (CNC) technology to automate the process, they differ in the type of motion used to remove material from a work-piece.

CNC Turning:

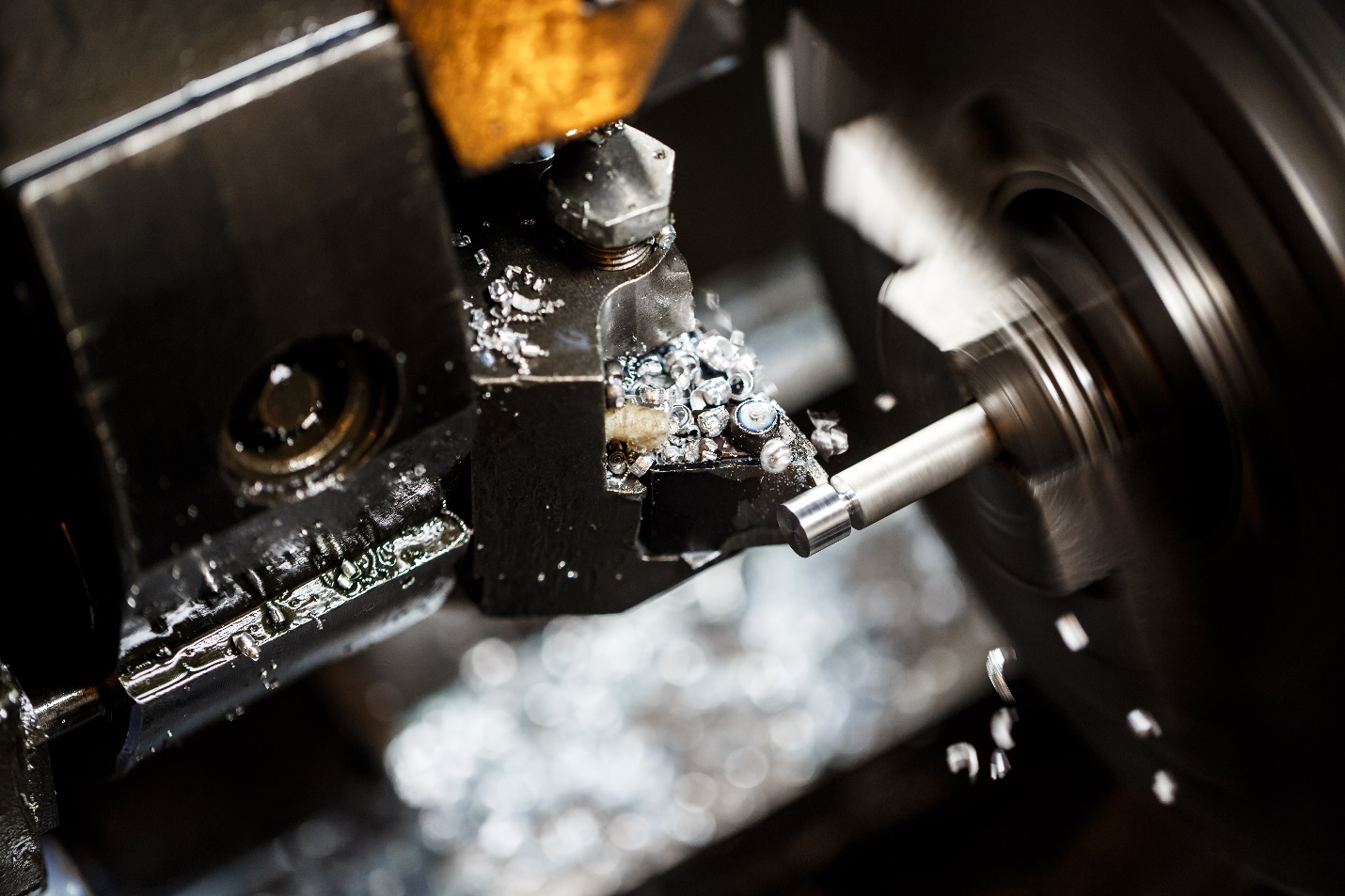

CNC turning is a process where a work-piece is held in a chuck or collet and rotated while a cutting tool is fed into the material to remove excess material and create the desired shape. The cutting tool is typically fixed and moves in a linear motion, while the work-piece rotates on its axis. This allows for the creation of round, cylindrical, or conical shapes. CNC turning is commonly used to create parts such as shafts, bushings, and threaded components.

CNC Milling:

CNC milling is a process where a cutting tool is moved in multiple axes to remove material from a work-piece to create a desired shape. The workpiece is typically held stationary on a table while the cutting tool moves in multiple directions, including up and down, side to side, and in and out. This allows for the creation of complex 3D shapes with a high degree of precision. CNC milling is commonly used to create parts such as brackets, housings, and molds.

Differences and Applications:

While both CNC turning and CNC milling utilize computer-controlled machines to automate the machining process, they differ in their application and the type of parts they can produce. CNC turning is best suited for creating round or cylindrical parts with a high degree of accuracy, while CNC milling is better suited for creating complex 3D shapes with a high degree of precision. Additionally, CNC turning is typically faster than CNC milling for producing simple round parts, while CNC milling is faster for producing complex parts with multiple features.

In summary, CNC turning and CNC milling are both important manufacturing processes that are used to create complex parts with a high degree of accuracy and precision. Each process has its own strengths and limitations, and the choice between the two depends on the specific requirements of the part being produced.

Conclusion

CNC turning and CNC milling are two important manufacturing processes used to create custom-designed parts with a high degree of accuracy and precision. While both processes utilize computer numerical control (CNC) technology to automate the machining process, they differ in their application and the type of parts they can produce. Click here