Sheet metal: what is it? The term “sheet metal,” as employed by sheet metal fabrication workers, refers to a thin, flat sheet of metal.Because sheet metal is such a versatile type of metal, it is frequently utilized in processes involving metalworking.

It can be shaped into a variety of things, including everyday objects and intricate automotive parts as well as substantial structural components.

The thickness of sheet metal can fluctuate; with sheets as thin as 3 millimeters in thickness and thicker pieces that are structural or plate steel and are used by boiler maker platers.

Sheet metal can be made of a number of different metals, including but not limited to:

Titanium, aluminum, copper, steel, brass, and pewter

How does sheet metal fabrication function?

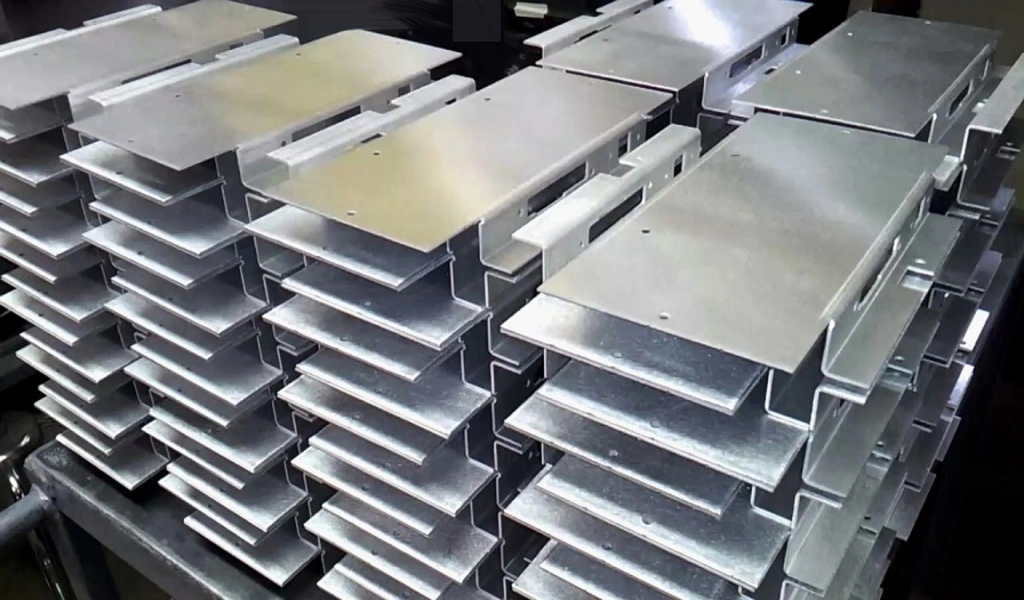

To put it simply, the process of making products from sheet metal is known as sheet metal fabrication.

Sheet metal can be made in a number of different ways. Most of the time, high-tech machinery is used to cut, bend, and form the metal into any shape you want. We’ll talk more about these processes later.

Draftsmen will use computer-aided design applications to adapt the preliminary designs and plans into technical drawings that are ready for production. This is how the process works from conception to production.

A 3D graphic simulation of the finished product will be created from these designs to show how the finished construction will look.

After that, the 3D CAD files are turned into machine code, which tells a machine how to cut and shape the sheets into the final part with precision.

What can be done with it?

Since sheet metal fabrication can be used for a lot of different things, asking this question is like asking, “How long is a piece of string?” There is no one solution.

The process of sheet metal fabrication can help you create the ideal product, whether you want to make architectural items or something that is both useful and functional. Check out our case studies to learn more about how sheet metal fabrication can be used.

You can see for yourself the kinds of goods we’ve made for our cherished clients.

What are the components of sheet metal fabrication?

Sheet metal fabrication, as previously mentioned, is done with machines that are operated by skilled engineers. These engineers frequently execute a comprehensive plan based on the customer’s specifications, just as we do at CSM.

In order to guarantee that you receive the ideal metal product, we develop, design, and manufacture bespoke type of metals in accordance with your requirements and budget.

Some of the methods used to manipulate sheet metal are as follows:

Forming

The majority of sheet metal fabrication involves some form of forming. Mechanical deformation is used to create metal parts and objects during the forming process.

To put it another way, the metal is reshaped without affecting its volume or size. The metal might need to be bent, rolled, laser rust removal or stretched to get the shape you want.

Bending

A piece of metal is bent in such a way that its shape is altered without affecting its volume. Metal is frequently bent into one of the following three shapes with specialized machinery: a channel shape, a V shape, or a U shape.

Using a press brake, which presses the metal between a knife-edge top tool and a vee-shaped bottom tool to shape the material to the desired angle over lengths of up to 10 meters, is the most common method of bending. Check out some of the metal angles from fastmetals.com.

The process of bending metal is not only one of the most cost-effective methods for fabricating sheet metal, but it is also extremely adaptable.

Using bending techniques, anything from small fixings like brackets to much larger pieces like shipping containers can be made.

For more details, visit our blog, “The Power of Bending Metal.”

Welding

Welding is another common method of fabricating sheet metal. The process involves heating metals to a high temperature and then cooling them so that they take on their new shape.

Rolling

This method is mostly used when the metal needs to have a smooth, curved surface. Roll forming, for instance, is the best method for creating cylinders, cones, and rounded architectural features.

The metal is run through a series of rolls in the process until it has the right width and curve. It’s impressive to see the process in action!

Punching:

If you need holes or a textured finish, punching might be the best method of fabrication. When you want to cut holes in metal of varying sizes and shapes, you use punching.

Using a punch and a die, it is done by applying pressure to the material on both sides.

Embossing

By passing a sheet of metal between rolls of the desired pattern, this method of metal forming creates raised or sunken designs in sheet material.

We can weld and polish the edges of the desired shapes at CSM using our extensive experience in this field to produce a high-quality finish.

Cutting

In the past, a specialized saw was used for all metal cutting.

Even though it works well, this sometimes leaves rough or imperfect edges. Fortunately, there are now a variety of cutting methods that can shape the metal to your specifications.

When precision is of the utmost importance, plasma torches, laser cutting, and high-powered water jets are utilized.

The method used will be determined by the project budget and the required finish.

Tooling

Mold Because the design of a tooling mold is typically one-of-a-kind, a metal fabrication company must completely redesign the equipment.

Experts produce components with intricate and complex geometry using tools like 5-axis CNC machinery.

Our Haas VM-6 mold maker machining center at CSM is a five-axis machine with three linear axes (X, Y, and Z) and two rotational axes (A and B) that work together to perform intricate surface machining.

The cutting tool is moved across the linear axes and rotates on the A and B axes so that the machine can approach the workpiece from any direction.

We produce high-quality products on time and within your budget by employing industry-leading software to design effective and optimized tool paths that reduce machining time and, consequently, cost.

Related CTN News:

Top Consideration When Buying a High-Quality Mulching Machine

How to Choose the Best Cannabis Seeds: Buying Guide

Thailand Issues 10 Step Guide on Cannabis to Tourists

⚠ Article Disclaimer

The above article is sponsored content any opinions expressed in this article are those of the author and not necessarily reflect the views of CTN News