Though they’re not found atop every building, you have definitely seen a cooling tower before. Nuclear power plant chimneys are the biggest example of an industrial cooling tower, though you can spot more compact units on factory roofs and commercial buildings all around the city.

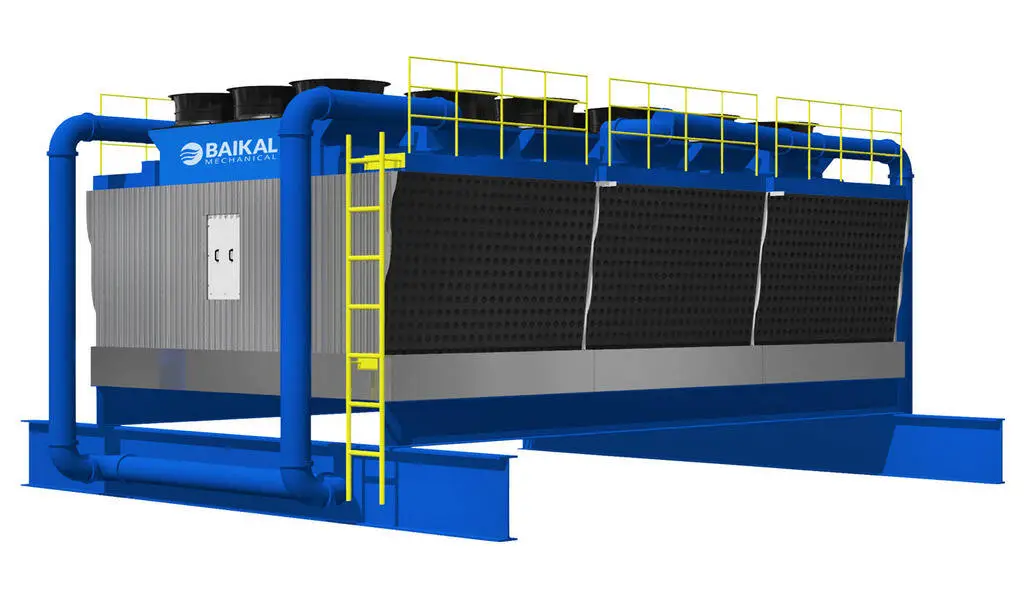

Baikal Mechanical has helped countless businesses find a cost-effective solution to cooling their workspaces through cooling towers. Learning how they work – and how they could work for you – is a worthwhile pursuit that can save you time and money.

What is a Cooling Tower?

It won’t surprise you to learn that a cooling tower is a tower that cools a building, as part of a larger HVAC system. In essence, the cooling tower is a specialist heat exchanger, which uses water-cooling technology to aid the function of internal HVAC equipment.

In the process of industrial air-conditioning, a vast amount of hot water is created. This isn’t optimal, as a chiller requires cold water to function normally and reduce temperatures inside the building. It is the job of the cooling tower to expel building heat upwards whilst using cold, dry air to cool the water, which is then pumped back into the chiller.

Industrial cooling towers are essential for such buildings as power stations, chemical processing plants, and resource mills to ensure safe working conditions and avoid precious machinery overheating. At the same time, largescale commercial settings, such as hotels, shopping centres and airports, use cooling towers to keep thousands of visitors comfortable.

It’s also imperative for these places to have cooling tower parts on hand for any repairs and maintenance that needs to be done.

How do HVAC Cooling Towers work?

Cooling towers work by having water and air contact each other in a highly controlled way. Hot water enters the unit, which is dispersed as droplets through nozzles. This increase the surface area, meaning there is greater heat transfer. At the same time, the top fan is drawing the incoming air upwards, which will absorb heat from the water as it rises.

(Creative Commons Licence Image)

After this evaporation, the remaining water simply falls to the bottom of the chamber. It is collected in a basin, before being pumped back into the building, where it will be used to once more lower inside temperature.

Types of Cooling Tower

There are a few distinctions to note when it comes to cooling tower systems.

1. Cross-flow vs. Counter-flow Cooling Towers

When it comes to factory-assembled cooling towers, there are two main configurations, both of which can benefit from a Baikal Mechanical retrofit. They differ in how air is taken in and dispersed, where each example has its own advantages and disadvantages.

In cross-flow cooling towers, water falls downwards vertically while air flows in horizontally. Consequently, air has slightly shorter contact time with the hot water, thus more air is needed causing greater power consumption. However, the air doesn’t need to go through the distribution system, so gravity-flow hot water basins can be installed.

In counter-flow cooling towers, water again falls downwards vertically but air flows from the bottom of the tower. Both forced and induced draft fans are used, along with four air inlets, as opposed to only two in a cross-flow set-up. Running costs are typically lower and as the water distribution is closed-off lateral piping, there’s less risk of algae buildup and maintenance is more convenient.

1. Induced Draft vs. Forced Draft Cooling Towers

Just as the position of fed air can vary, so too can the way in which air is driven through the cooling tower. In an induced draft system, axial fans are mounted at the top of the unit, creating low pressure and pulling air upwards.

Forced draft configurations rely on an inlet fan mounted at the bottom of the tower, which pushes air upwards. This position is of course more convenient for maintenance, and as the fan components are in the dry air stream, lifespan is usually longer.

Having a fan positioned at the bottom of the chamber will increase noise levels. However, it is also possible to install centrifugal fans as part of your forced draft system, which would further reduce noise.

3. Factory-assembled vs. Field-erected Cooling Towers

As you can imagine, it’s a logistic nightmare to transport an entire cooling tower in a single lorry load. Factory-assembled towers are assembled in as few pieces as possible, where each sections is still small enough to be transported. These sections are commonly known as the factory-assembled products (FAP).

Field-erected cooling towers are assembled on-site, where all necessary components have been prefabricated and shipped to wherever the cooling tower is to be built. These pieces will be known as the field-erected product (FEP). It’s common practice for manufacturers to also provide labour and/or guidance so that the entire process is straightforward for the customer.

Benefits of a HVAC Cooling Tower

Cooling towers can have tremendous value for your business, improving efficiency and reducing long-term utility costs. With relatively little adaptation, you can keep visitors happier and employees productive by enhancing your existing HVAC system.

Installation and maintenance of HVAC cooling towers is a (cool) breeze, especially when you trust in Baikal Mechanical, who are driven by a promise of reliable equipment with minimal maintenance. An engineer can determine the best placement for your cooling towers, taking into account any natural shade and wind that would improve performance.

At the same time, a cooling tower system can help an organisation reduce their carbon footprint. By simply using the principle of dissipation, along with a fan or two, you can drastically reduce the strain, thus power draw, of your current air-conditioning set-up.

Also Check:

Kafka UI Monitoring Tools: Key Kafka Metrics for Monitoring Performance

iPhone 13 Discount on Flipkart: Enjoy Discounts and Exchange Offers Today

Microsoft Schools of Education in The Classroom: Are You Ready for SDE?

Playtech Adds Rainbow Riches to their Inventory