In contemporary electronics, flex PCBs offer flexibility, lower space requirements, and better reliability for complex designs. Therefore, selecting an adept flex PCB manufacturer is vital as their expertise in layer stack-up, material selection, and intricate trace routing could influence the PCB’s performance.

As a result, thorough vetting for manufacturers’ technological proficiency and production capabilities is the prerequisite for the all-in-one integration of flex PCBs in cutting-edge electronic applications.

Understanding Flex PCBs

l What Is Flex PCB?

Flex PCBs are advanced electronic interconnects characterized by their flexible polyimide or polyester film substrate. Flexibility is their defining feature, allowing them to bend, twist, and fold for space and weight savings. These PCBs include thin copper conductor layers and are used in high-density applications. They can be single-sided, double-sided, or multilayered. Their construction may involve stiffeners, surface finishes, and vias tailored by flex PCB manufacturers.

l Features of Flex PCBs

The defining feature of flex PCBs is their flexibility, which facilitates bending, twisting, and folding. This characteristic is particularly valuable for applications where space and weight savings are crucial. The boards often incorporate thin copper conductor layers, contributing to their lightweight design.

l Applications of Flex PCBs in Various Industries

Industrially, flex PCBs have renovated electronic design in sectors demanding compact and flexible solutions. For example, their lightweight and space-efficient nature helps the aerospace industry to shrink payload weight and volume. Similarly, in consumer electronics, they are used in foldable smartphones and wearables for reliable connections in flexing environments. Medical devices benefit from flex PCBs through miniaturized, flexible biosensors and diagnostic equipment.

Finding the Right Flex PCB Manufacturer

1. Why the Manufacturer Selection Matters

Selecting the right flex PCB manufacturer is critical because the quality, consistency, and performance of flexible printed circuit boards depend on PCB flex manufacturing. A competent manufacturer ensures adherence to design specifications, material quality, and precision in fabrication for the final product’s functionality. But how to find the right one could become a very complex question. Here is some guidance for you.

2. Steps for Identifying the Right Manufacturer

l Identifying Your Flex PCB Requirements

Firstly, carefully understanding your flex PCB requirements is essential. It includes determining the specific type of flexible PCB (single-sided, double-sided, and multilayer), the required flexibility level, and the intended application environment (e.g., high temperature, chemical exposure). For example, a double-sided flex PCB with heightened thermal management might be necessary for high-performance computing applications.

For more information about full product assembly, please read Unlocking Efficiency: A Guide to Successful PCB Manufacturing and Full Product Assembly.

l Review Manufacturers’ Capabilities

Subsequently, assess the technological capabilities of potential flex PCB manufacturers. It examines their proficiency in progressive manufacturing techniques, including laser drilling for micro-vias or precision etching for fine line widths. Also, evaluate their design and development process, quality control (QC) measures, and capability to handle your projected production volume. For instance, a manufacturer using automated optical inspection (AOI) systems will offer higher accuracy in defect detection, which is essential for high-density flex PCBs.

l Evaluate Expertise and Experience

Then, scrutinize the expertise and experience of your flex PCB manufacturers. Investigate their track record in applications similar to yours. Experienced manufacturers often have refined processes and insights that can contribute to enriched performance and permanence of the PCB. For example, a manufacturer experienced in aerospace applications will be familiar with this sector’s standards and the unique challenges.

l Check Certifications and Quality Standards

Moreover, verifying the certifications and devotion of the prospective flex PCB manufacturers to quality standards is indispensable. Consider certifications like ISO-9001 for quality management or specific industry standards for flex PCBs. Remember, these certifications indicate a manufacturer’s obligation to quality and uniformity. For instance, an ISO-9001-certified manufacturer would have systematic processes to guarantee product quality and customer satisfaction.

l Enquire on Customization and Design Support

Last but not least, inquire about the manufacturer’s capabilities in customization and design support. A manufacturer that deals with extensive design support can assist in augmenting your flex PCB design for manufacturability. For example, a manufacturer offering design support might suggest material substitutions or layout changes for better flex PCB durability in a wearable device.

YLC King: The Best Flex PCB Manufacturer

YLC King is a premier manufacturer of flex PCB with custom PCB design and fabrication services. Its expertise covers applications like communications, agriculture, and consumer electronics.

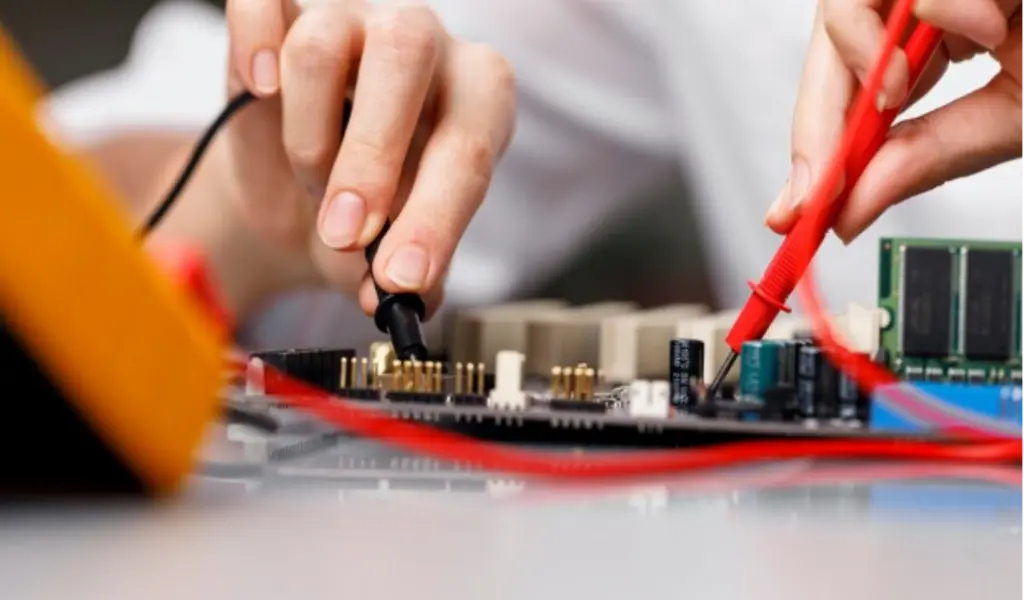

The process encompasses multi-stage PCB development, so designs transform into production-ready products. It includes a two-step manufacturing process, starting with board fabrication and culminating in assembly, followed by post-manufacturing testing.

Further, its capabilities extend to substrate material and board thicknesses via size, track width, and surface treatments. YLC King handles everything from single-sided to complex multilayer boards, with flexible and flexible rigid options available. Visit the YLC King website to learn more about PCB manufacturing!

SEE ALSO: Is Gold Still A Good Investment In 2023?: Shining Or Losing Its Luster?

⚠ Article Disclaimer

The above article is sponsored content any opinions expressed in this article are those of the author and not necessarily reflect the views of CTN News