Milling machines, a cornerstone in the world of machining, are indispensable for precise shaping and cutting of materials. Foundational in industries such as manufacturing, construction, and automotive, these machines come in various types, each tailored to specific needs.

This guide delves into the intricacies of milling machines, comparing different types to aid in making an informed decision.

Overview of Main Types of Milling Machines

Vertical Milling Machines:

Spindle Position: Vertical

Ideal For: Precise material removal from the surface

Common Uses: Intricate work and smaller items, perfect for detailed milling operations like die sinking and engraving.

Horizontal Milling Machines:

Spindle Position: Horizontal

Ideal For: Cutting along the length of the workpiece

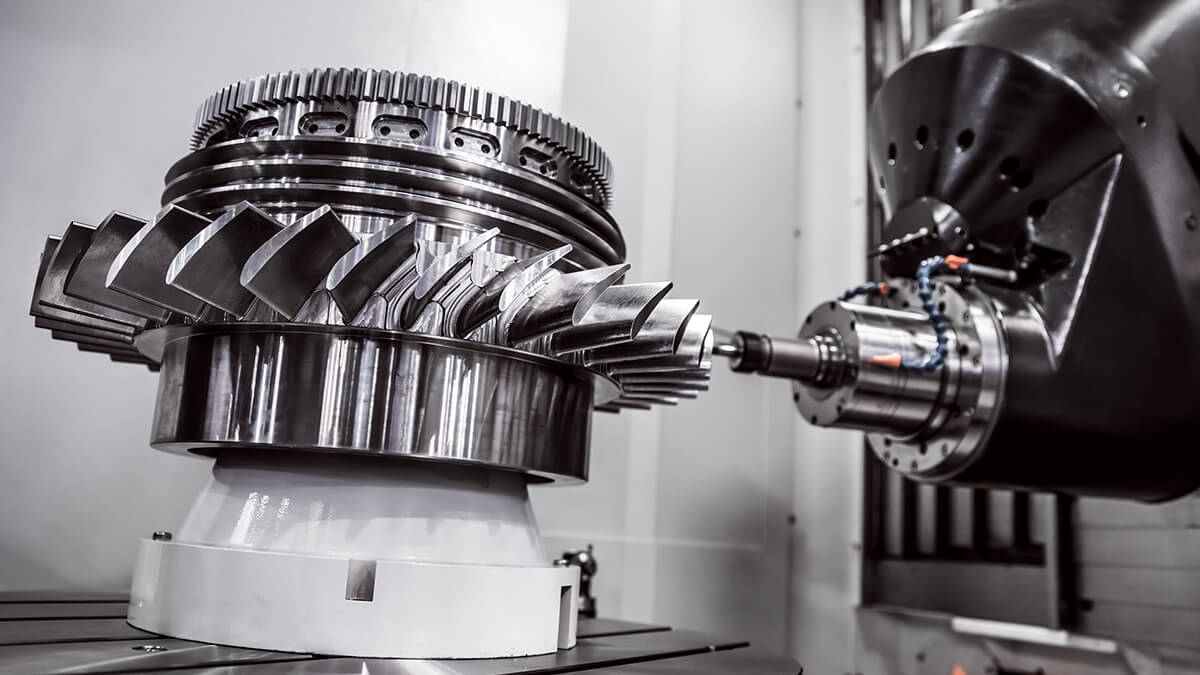

Common Uses: Heavy-duty tasks, suitable for large and heavy workpieces, often used in high-volume projects like gear manufacturing.

Universal Milling Machines:

Features: Blend of vertical and horizontal milling capabilities

Ideal For: A wide range of machining operations

Common Uses: Versatile applications, from tool rooms to production shops, handling a variety of shapes and sizes.

CNC Milling Machines:

Features: Computer-controlled precision

Ideal For: Complex designs with high precision requirements

Common Uses: High-volume production and intricate parts, especially in industries where accuracy and repeatability are paramount.

Key Features in Milling Machine Comparisons

Spindle Speed and Power: These parameters dictate the machine’s cutting capabilities. High spindle speeds coupled with robust power enable the machine to handle a variety of materials efficiently.

Table Size and Travel: This aspect determines the maximum size of the workpiece that the machine can handle, as well as the range of motion available for milling operations.

Control Systems and Automation: Modern milling machines often feature advanced control systems for precise operations. Automation in CNC milling machines allows for intricate designs that would be impossible to achieve manually.

Advantages and Disadvantages of Different Milling Machines

Vertical Milling Machines:

Pros: User-friendly, ideal for detailed work, space-efficient design for smaller workshops.

Cons: Limited in handling large or heavy workpieces, less suited for bulk production.

Horizontal Milling Machines:

Pros: Capable of handling heavier and larger workpieces, suitable for large-scale industrial applications.

Cons: Requires more floor space and complex setup, may have higher operational costs.

Universal Milling Machines:

Pros: Flexibility in performing both vertical and horizontal milling operations, broad application range.

Cons: Generally more expensive and may require more maintenance due to their complex design.

CNC Milling Machines:

Pros: High accuracy and repeatability, customizable for specific tasks, suitable for complex and intricate designs.

Cons: Higher initial investment, requires skilled operators and programmers, ongoing maintenance can be costly.

Influence of Size and Power on Functionality

Larger Machines: These are typically more powerful and capable of handling demanding tasks like cutting tougher materials and managing larger, heavier workpieces. They are ideal for industrial applications where heavy-duty milling is a regular requirement.

Smaller Machines: These are designed for precision and detail, suitable for smaller components and intricate designs. Their agility makes them a favorite in tool-making, prototyping, and custom manufacturing.

Diverse Industry Applications

Automotive Industry: From engine parts to intricate interior components, milling machines play a critical role in automotive manufacturing.

Aerospace Industry: The precision required in aerospace components like engine parts and aerodynamic panels is achieved through advanced milling processes.

Medical Industry: Milling machines produce highly precise and customized parts for medical devices, implants, and prosthetics.

Construction Industry: Milling machines are used for various construction tasks, including milling asphalt for road construction and creating structural components.

Guidelines for Optimal Milling

Speeds and Feeds: Selecting the correct spindle speed and feed rate is vital for the quality of the milling process. It affects the surface finish, tool life, and overall machining efficiency.

Lubrication and Cooling: Proper lubrication and cooling systems are essential to prevent overheating and to prolong the life of both the tools and the machine.

Precision Measurement and Alignment: Accuracy in milling is paramount. Regular calibration and alignment checks ensure the precision of the machine and the quality of the parts produced.

Safety Precautions: Adhering to safety protocols, including the use of PPE like safety glasses and gloves, is crucial to prevent accidents and ensure safe operation.

Recent Technological Advancements

Automation and Robotics: The integration of robotics in milling machines has led to increased efficiency and the ability to perform complex tasks with minimal human intervention.

High-Speed Machining: This technology enables faster production times and finer finishes, optimizing the milling process for various materials.

Digitalization and Connectivity: The integration of IoT and cloud-based technologies allows for real-time monitoring and data analysis, improving machine efficiency and predictive maintenance.

Advanced Control Systems: These systems enhance the machine’s capabilities, allowing for easier operation and more precise control of the milling process.

Conclusion

Selecting the right milling machine involves careful consideration of various factors including the type of machine, its features, and the specific requirements of the industry it will be used in. With continuous advancements in technology, milling machines are evolving to offer greater precision and efficiency, making them more indispensable than ever in the world of manufacturing.

⚠ Article Disclaimer

The above article is sponsored content any opinions expressed in this article are those of the author and not necessarily reflect the views of CTN News