Lifestyles

Introducing Tungsten Carbide Material

What is tungsten carbide? Tungsten carbide is a materials engineering innovation. It is created by combining tungsten and carbon atoms together to create a strong, wear resistant material. This makes it an ideal choice for many industrial applications where durability and strength are required.

Tungsten carbide material is widely used in a number of industries due to its unique properties. In aerospace, tungsten carbide is used to create turbine blades that are able to withstand high temperatures and reduce drag. In the automotive industry, tungsten carbide is used to create car parts that are resistant to wear and tear. In medicine, tungsten carbide is used in bone cutting instruments and other surgical tools.

The process of creating tungsten carbide begins with creating a powder mixture of the two materials, tungsten and carbon. This mixture is then placed in a furnace and heated to extremely high temperatures. Once it reaches the desired temperature, it is allowed to cool so that the carbide can form. Finally, the carbide undergoes a process called sintering which strengthens and hardens it.

Tungsten Carbide has a number of advantages over other materials used for similar applications. It has a high hardness which makes it resistant to erosion and able to withstand high compression yield forces. Additionally, its melting temperature is very high, making it ideal for use in products that will be exposed to extreme heat conditions such as turbine blades or drill bits.

Tungsten carbide rods are an essential part of many industrial applications. They are created by combining tungsten and carbon atoms together to create a strong, wear resistant material. This makes them an ideal choice for many applications where durability and strength are required.

Tungsten carbide rods have a number of advantages over other materials used for similar applications. They have a high hardness which makes them resistant to erosion and able to withstand high compression yield forces. Additionally, their melting temperature is very high, making them ideal for use in products that will be exposed to extreme heat conditions such as Carbide End Mills or drill bits.

One of the most important advantages of tungsten carbide rods is that they can be produced in a variety of different sizes and shapes. This allows manufacturers to create products that meet the specific needs of their application. Additionally, tungsten carbide rods can be cut and machined into a variety of different shapes, allowing for even more customization.

HSS comparison to tungsten carbide

The main difference between HSS and tungsten carbide is the amount of carbon that is

present in each one. Tungsten carbide has a higher concentration of carbon, which gives it its unique properties. HSS, on the other hand, has a lower concentration of carbon. As a result, HSS is not as strong or wear-resistant as tungsten carbide. Some advantages of tungsten carbide over other materials are its high hardness, resistance to erosion, ability to withstand high compression yield forces, and high melting temperature.Tungsten carbide is a strong, wear-resistant material that is created by combining tungsten and carbon atoms together. This makes it an ideal choice for many industrial applications where durability and strength are required.

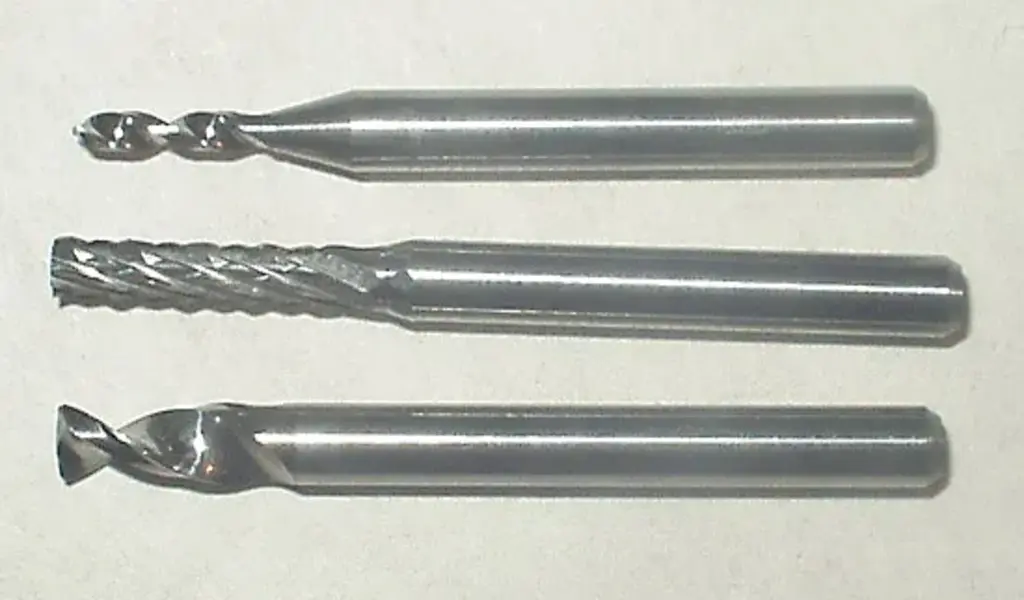

Used for making CNC cutting tools

Tungsten carbide material is mainly used to make CNC cutting tools, which are an essential part of the modern manufacturing process. They are computer-controlled tools that can cut, drill, or mill a variety of materials. CNC cutting tools are used in a wide range of industries, including aerospace, automotive, medical, and general manufacturing.

There are many benefits to using CNC cutting tools. They can produce parts with high precision and accuracy. Additionally, CNC cutting tools can be used to create complex shapes and designs that would be difficult or impossible to create with traditional methods. CNC cutting tools also allow for a high degree of repeatability, meaning that parts can be reproduced exactly as intended every time.

There are three main types of CNC cutting tools: routers, mills, and lathes. Routers are the most common type of CNC cutting tool and they can be used to cut a variety of materials. Mills are similar to routers but they have a rotating cutter head that allows for more complex cuts. Lathes are designed for cylindrical objects and they use spinning cutter heads to shape the material around a central axis.

No matter what type of industry you’re in, chances are good that CNC cuttingtools can help you improve your product quality and efficiency. If you’re looking for ways to take your business to the next level, investing in some high-quality CNC equipment is a great place to start.

People Also Read:

How Can Hair Extension Salon Assist You And How To Hair Girl?

Three Possible Replacements for Sean Dyche at Burnley

Cordless Drills: Perform Repairs Easily and Quickly

![Play Online Blackjack In Australia [2024]: Top 10 Online Australian Blackjack Sites 16 Play Online Blackjack in Australia [2024]: Top 10 Online Australian Blackjack Sites](https://www.chiangraitimes.com/wp-content/uploads/2024/03/word-image-303235-1-80x80.jpeg)