Learning

Understanding the Fundamentals and Benefits of Hydraulics Systems

You go to the dump truck from the lift, and you see hydraulics rolling along the way. This robust mechanism is driving out some of the most massive machines. Hydraulics can bear tremendous loads and run at high speeds. They are widespread on building sites and a range of other applications.

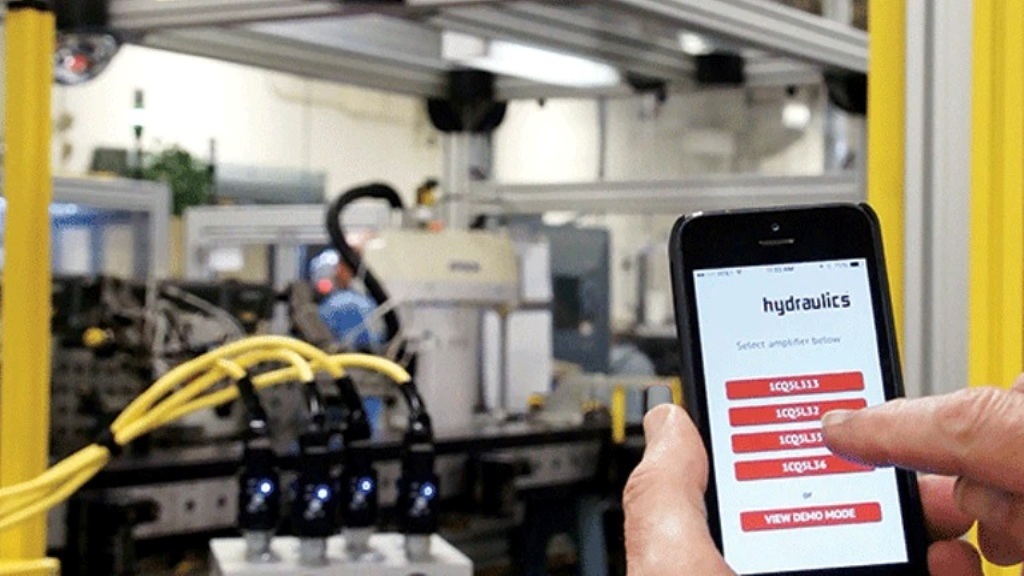

The hydraulic systems are numerous, all working according to the same energy concepts. Hydraulic pumps strain a liquid, and their action is used to fuel cranes and vehicles. If you are looking for someone to repair your hydraulic systems, be sure to look for BOA Hydraulics. We provide satisfactory repairs, and we will teach you what you need to know about hydraulic systems in this posting.

How is the hydraulic system functioning?

Any of the fundamental ways that a hydraulic machine operates are possibly already understood. You already know from your experience that solids are typically not squishable. If you gather and attempt to pull a sturdy object like a pen or wood piece, the materials will not happen. You’re not going to pinch or squish. Liquid functions in the same manner. It’s incompressible, but as you put pressure, it doesn’t lift. It takes up the same room as though it hasn’t been squeezed. In a syringe, imagine water. If you cap your finger at the end of it and attempt to press it down, no water or dip can go anywhere.

In hydraulics, the compression is a significant contributor to their activity. You usually press the plunger down in the same fluid, except though you don’t place too much air, you expel the water at high speed from the narrow end. You put a weight on the water by pressing down the plunger. The water will attempt, however, to escape, in this situation, through a tiny exit at high pressure. We will increase the force of this program and use it to control more complicated machines.

What is the difference between Open and Closed Hydraulics?

Hydraulic systems open and closed apply to various ways in which pump pressure is minimized. This will lead to reduced wear and tear.

The pump operates in an open system, pushing oil into the pipes without pressurizing up. Two hydraulic reserves connect both the inlet to the pump and the return valve. These systems are also known as “open core” systems due to the neutral, open central valve direction. Hydraulic fluid is returned to the tank in this situation. The liquid from the pump is moved to the system and returned to the reservoir. In the circuit, the excess fluid to the tank can also be diverted through a relief valve. The liquid is usually kept clear by filters.

The valve returns directly to the hydraulic pump entry in a closed mechanism. The fluid is driven in a continuous loop by a single central pump. A valve also stops the pump from sending oil instead to the accumulator where it sits under pressure. Until it is triggered, oil stays in a place of force but does not move. A charging pump supplies low-pressure cool, filtered diesel. This move holds the loop under control. In hydrostatic transmissions, a closed system also uses a pump to control multiple systems.