Learning

Methods to Clean CNC Precision Machined Parts

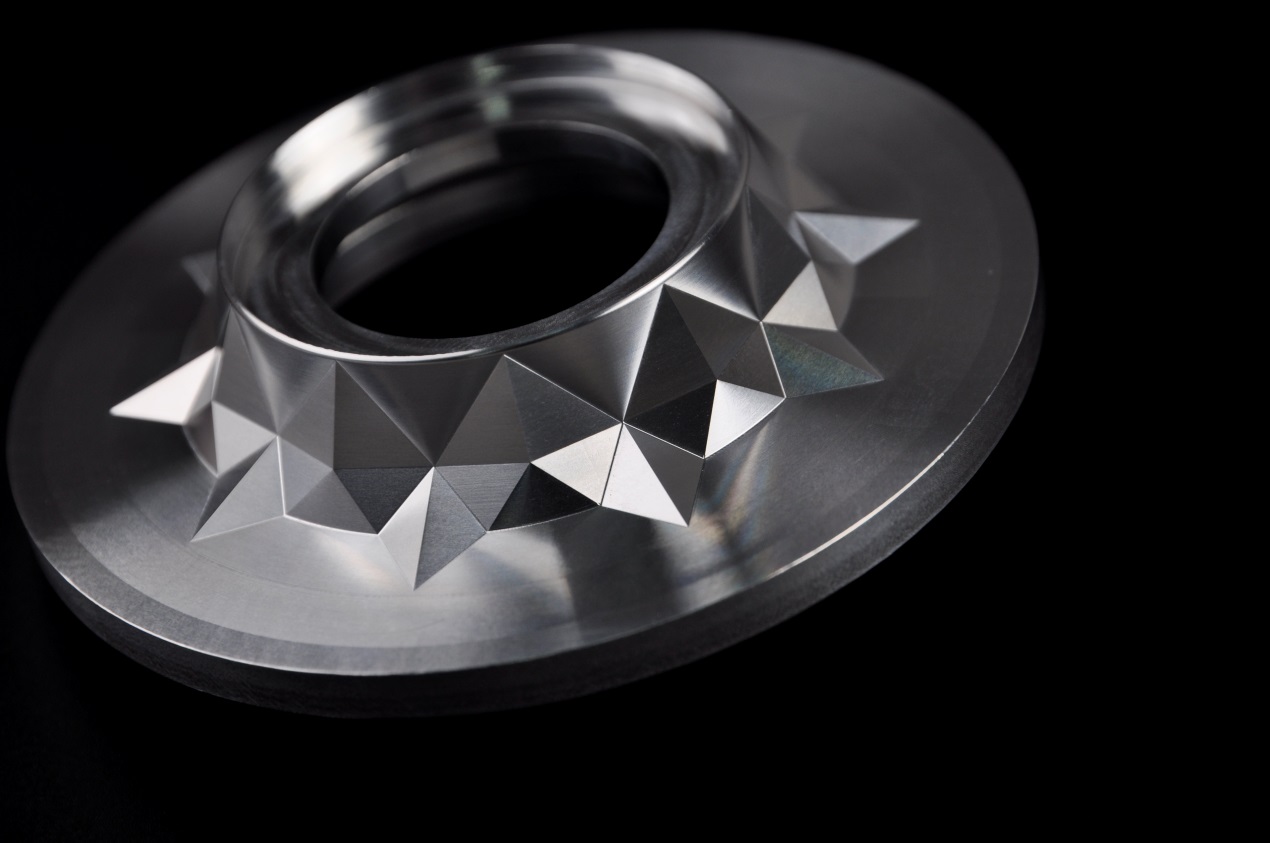

If you’re new to the manufacturing world, a question will linger in your mind: what is CNC precision machining and how CNC precision milling parts are cleaned?

CNC precision machining involves computerized cutting tools with exact specifications along with G-Code programs.

When CNC Precision Machining is utilized it catches out the debris, grease, burr, dirt, casting sand, oil, iron filling, rust, etc.

This debris not only shortened the life period of CNC precision machines but also affected the assembly quality.

So, cleaning the CNC precision milling’ parts is an important step to avoid costly maintenance and faults in products.

In this guide, we will share some important steps which will help to clean the visible surfaces, blind holes, and small cavities of CNC precision machines.

Steps To Clean CNC Precision Machines’ Parts

Before removing dust, make sure from which materials the part is made. A plastic part needs a different cleaning method than an aluminum or steel part.

Similarly, cleaning blinds holes or complex cavities is more challenging than simple parts.

Before exploring the cleaning steps, let’s make out how chemistry affects the process.

Why Chemistry Matters?

In the cleaning process of CNC milling parts, some people prefer cleaning with tap water, distilled, purified, and deionized water does a great job.

If the parts are stuffed with oil, grease, chips, and coolant, then high-alkaline soap is required for deep cleaning.

Note: this high-alkaline soap can be dangerous for aluminum parts or can discolor them, therefore you need a different soap to clean aluminum parts.

Let’s know the cleaning steps of CNC machines’ parts for deep understanding.

Taking a bath

It is a common cleaning method where you put the parts in a bath of cleaning solution: solution means water-based solution, not solvents.

Agitation of the bath will enhance the cleaning process. Moreover, it will enhance the life service of the CNC Precision Machining parts.

Tiny bubbles

It is another method of cleaning. As we know human ears can hear the voice up to 20 kHz. And beyond this sound, ultrasound appears.

For difficult cleaning parts, an ultrasonic system is used. In this process, a tank is used filled with water or a cleaning solution which is fitted with sound transducers.

It is also known as the “stereo system in water”. The transducers work like a speaker which emits high-frequency sound into the bath. And most manufacturers do not know that a 40 kHz frequency is used to clean the parts.

At 40 kHz each oscillation gives forth a bubble, so in one second you will receive 40,000 bubbles from each transducer.

When each bubble meets the part it cleans the dust or oil very gently. Lower frequency means more rigid or aggressive cleaning.

A lower frequency like 25 kHz is used to remove mould or rust, especially from the injection moulding process. Higher frequencies ranging from 68 kHz to 132 kHz produce small bubbles which reach confined spaces such as screw threads or small passages in CNC milling parts.

Multiple frequencies are used in multiple cleaning baths.

Spray wash

There is another method to spray the parts and clean them. This system provides cleaning of parts with spray nozzles aimed to clean the parts directly with spray.

The method has good cleaning properties and this is usually used in less complicated parts and shapes.

The Aquamate cabinet system is also used to clean the CNC milling parts. You can put the parts then close the door and tap the button and walk away. This system automatically cleans the parts.

CNC cleans: a high-pressure clean/deburr

All the spray pressure systems produce 100 to 2,000 psi, but a CNC-driven ram catches the part and moves it to deburring Station.

There in deburring station high-pressure spray nozzles are used to clean or deburr. Each nozzle has distinct features and functions differently.

High pressure is used in deburring of 4-axis CNC configuration. Pressure is available up to 10,000 psi.

Environment-friendly solvent cleaning

If you want an environmentally friendly cleaning of the parts you can use self-contained solvent cleaning in the washing system. These systems seal the solvent inside the parts. Most interestingly the system can be reused with the same solvent indefinitely.

You put the parts in a basket and load them with a washer system. Firstly it cleans the air from the cleaning part.

Then the system introduces the solvent. Ultrasound, rotation, or mechanical oscillation increases the solvent action.

We all love natural calmness and do not want to hurt nature. That is the reason this method was introduced to cope up with environmental challenges.

Scrubbing method

It is a simple method and does not require much time to invest. What you need to do is keep the parts in a container which is filled with kerosene, diesel, or other cleaning fluid.

Now scrub the parts with a rigid cotton pad or brush. It is simple and cost-effective but does not help in complex cleaning. It just helps in small parts or for small operations. For big ones or big parts, you should consider the above-mentioned procedures.

Final Verdict

Through this definitive post, we tried to inform you about CNC Precision Machining and how their parts are cleaned to remove dust or oil to enhance their life span for a longer time.

If you want to get the suitable result of parts cleaning, then you will need the right equipment, suitable chemistry, proper cycle time, right temperature, and right ultrasonic frequencies.

If you find any ongoing challenge in parts handling or cleaning or if you want to run high volumes, or parts need integrity, then you need to investigate different systems to evaluate which can help out your CNC machines parts.

If you readers like our technical post please share it with your near and dear tech-lovers. Happy reading!

People Also Check:

Data Science Now Playing an Important Role in the Healthcare…

Learning About Bjorntoft Maskinfabrik and CNC Machines…