Learning

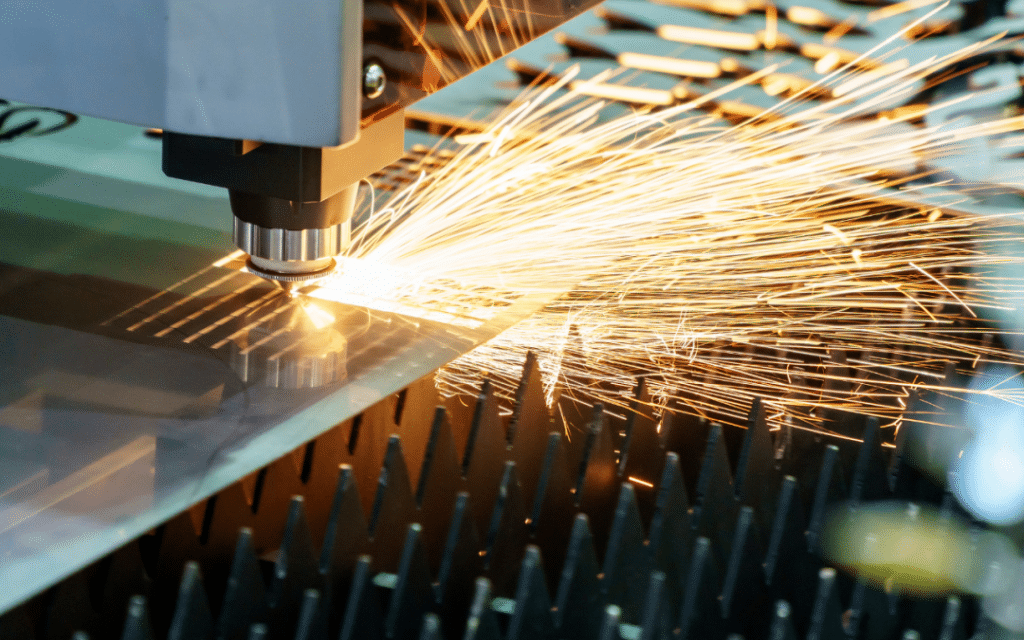

Learning the Benefits of a Fiber Laser Cutting System

The application of fiber optics is evolving. The advent of fiber optics into the modern, data-driven world has increased data transfer rates and volume. Fiber optics, made up of threads of diodes and transmit light beams, are used to transport information rather than phone lines or coaxial wires. The power to transfer DXTECH Laser Cutter beams has changed to lasers as the quantity of light channeled and magnified through fiber optic cabling enables a concentrated light beam that is 200 percent more productive than that of a CO2 laser and does not require the expensive optical spotlights usually encountered in laser cutting systems.

The following are the benefits of a fiber laser cutting system:

Substance for cutting mirrored material:

One of the biggest issues with utilizing a conventional laser is the reflecting material. There is a possibility that a laser will bounce off the shiny material, damaging the apparatus. As a result, conventional lasers manufactured by Elephant CNC are rarely utilized to cut brass, aluminum, and copper. However, using fiber-optic lasers, this reflecting material problem is no longer a concern, allowing for cutting these materials.

Increased cutting efficiency:

Another benefit of employing fiber optic laser cutting is that the friction coefficient is increased. A fiber-based laser can cut a straight line of 1mm thickness three times quicker than a conventional laser. This includes the ability to cut across materials, including stainless steel. When cutting through 2mm thickness, the time improvement drops twice as fast, although it is still a significant improvement.

There are no moving parts:

Moving components need more maintenance and raise operational expenses. Because light pulses are delivered over fiber optic cable, moving mirrors are not required to create the necessary laser. Other types of lasers use a fast rotating mirror to increase the power of the light. Regular maintenance is significant to prolong the life of the mirror. Productivity suffers as a result. However, if the periodic inspection is not conducted, the risk of material damage grows, which puts the laser offline and raises the operating costs.

Cost-effective:

The pricing is maybe the most important advantage of fiber laser cutting. This technology’s cost overhead provides huge savings, both in the original purchase and throughout the lifespan of the laser. For starters, unlike other laser technologies, it does not need the use of costly optical reflectors. Furthermore, the concentrating lens is not exposed but rather enclosed within the cutting head. As a result, when properly maintained, the focusing lens will last the lifespan of the fiber optics, rather than getting damaged and requiring constant maintenance, as is the situation with other laser diodes.

The precision of fiber laser cutting:

A fiber laser cutting equipment provides high precision in all metals that can be cut with a fiber laser. There have been no beam deviations with a fiber laser, ensuring a clean and exact cut every time. The sheet metal industry’s fiber laser technology is among the most sophisticated. This implies your laser is already utilizing the most cutting-edge technology available, making the whole cutting process more productive.